×

- Live Chat

- 1-888-788-9341

My Garage

My Account

Cart

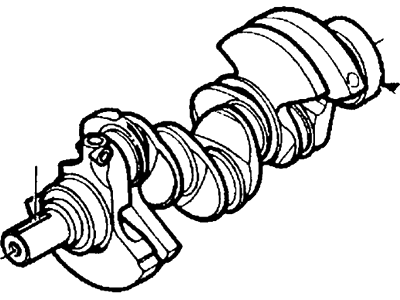

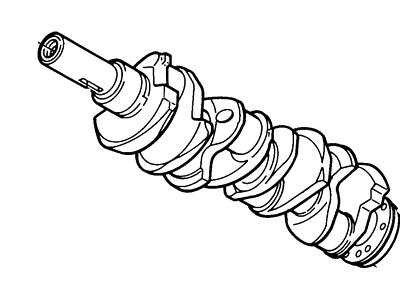

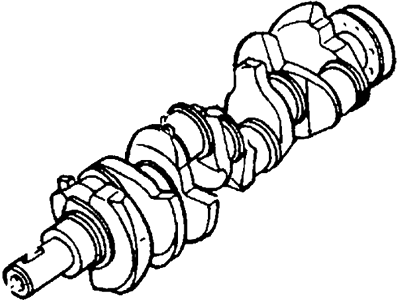

Genuine Lincoln Mark VII Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshafts found

Lincoln Mark VII Crankshaft

We provide a wide range of Lincoln Mark VII Crankshaft at the best prices possible. If you need Lincoln Mark VII Crankshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln Mark VII Crankshaft Parts Questions & Experts Answers

- Q: How to inspect and repair a crankshaft on Lincoln Mark VII?A: Remove burrs from crankshaft oil holes with stone/file/scraper. Chamfer oil holes to prevent bearing damage. Clean crankshaft with solvent and compressed air. Use brush to clean oil holes and flush with solvent. Rub penny on journals to check for copper embedding. Inspect for wear, scoring, pits, cracks. Magnaflux for hidden cracks. Measure journal diameter with micrometer for taper/out-of-round. Regrind if damaged/worn. Check oil seal journals for wear/damage. Repair or replace if necessary. Examine bearing inserts.

- Q: How to install a crankshaft on Lincoln Mark VII?A: Crankshaft installation is the first step in engine reassembly. The engine is flipped upside down, main bearing caps are removed, and new bearing inserts are placed. The crankshaft is carefully positioned and oil clearance is checked. The caps are installed and torqued in three steps. Grease is applied to the bearing surfaces and the crankshaft is placed back into the block. Crankshaft rotation and endplay are checked. For OHC engines, jack screws are used and the rear main oil seal is installed.

- Q: How to remove the crankshaft on Lincoln Mark VII?A: Inspect the endplay using a dial indicator or feeler gauges before taking out the crankshaft. If the endplay is more than the limit, then check for wear on crankshaft thrust surfaces. If necessary, label and number main bearing caps. On OHV engines begin from the center and loosen main bearing cap bolts gradually. In order to take off the crankshaft in OHC engines, follow this exact process. Replace main bearing cap bolts and lift out the crankshaft gently. Put back the caps in their original positions on the engine block and finger tighten their bolts.