×

- Live Chat

- 1-888-788-9341

My Garage

My Account

Cart

Genuine Mercury Lynx Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Wheel Cylinders found

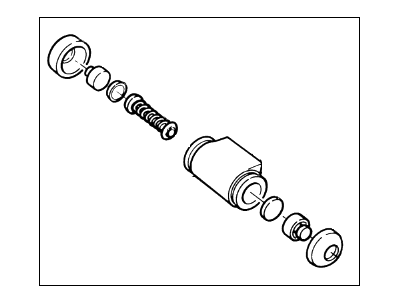

Mercury Lynx Kit - Wheel Brake Cylinder Repair

Part Number: E43Z-2128-A$13.73 MSRP: $18.75You Save: $5.02 (27%)Mercury Lynx Cylinder Assy - Rear Brake

Part Number: E43Z-2262-A$16.75 MSRP: $22.89You Save: $6.14 (27%)Mercury Lynx Cylinder Assembly - Rear

Part Number: E2FZ-2261-B$17.80 MSRP: $24.32You Save: $6.52 (27%)Ships in 1-2 Business DaysMercury Lynx Cylinder Assembly - Rear

Part Number: E2FZ-2262-B$17.80 MSRP: $24.32You Save: $6.52 (27%)Ships in 1-2 Business Days

Mercury Lynx Wheel Cylinder

We provide a wide range of Mercury Lynx Wheel Cylinder at the best prices possible. If you need Mercury Lynx Wheel Cylinder, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Lynx Wheel Cylinder Parts Questions & Experts Answers

- Q: How to overhaul and install a wheel cylinder on Mercury Lynx?A: If an overhaul is indicated, usually due to fluid leakage or sticky operation, explore all options before beginning the job. It is recommended to install new wheel cylinders for ease. If rebuilding the wheel cylinder, ensure that rebuild kits are available beforehand. Always rebuild both wheel cylinders simultaneously. To remove, loosen the wheel lug nuts, raise the rear of the vehicle, support it on jackstands, and block the front wheels before removing the rear wheel(s). Next, remove the rear hub/drum and brake shoes. Disconnect the brake line from the back of the wheel cylinder and plug it, then unbolt the wheel cylinder and remove it from the backing plate, cleaning the mating surfaces. For the overhaul, remove the bleeder valve, cups, pistons, boots, and spring assembly from the wheel cylinder housing. Clean the wheel cylinder with brake fluid, denatured alcohol, or brake system cleaner, and use compressed air to remove excess fluid and blow out the passages. Check the cylinder bore for corrosion and score marks; use crocus cloth for light corrosion, but replace the cylinder if defects are severe. Lubricate the new cups with brake fluid and assemble the brake cylinder components, ensuring the cup lips face inward. For installation, position the wheel cylinder and install the bolts without tightening them yet. Connect the brake line to the wheel cylinder without tightening it, then securely tighten the brake line fitting. Install the brake shoe assembly, followed by the brake drum, and adjust the wheel bearing. Finally, bleed the brakes.