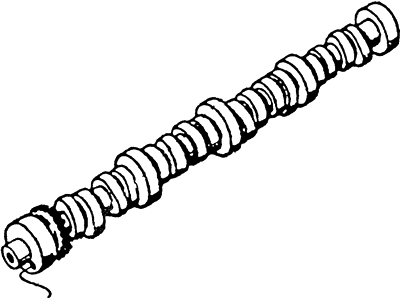

To investigate additional end play, and to assess lobe lift, unbolt the valve covers and the rocker arm assembly but leave the push rods in overnight. Turn the engine until the first push rod is on the top dead centre of the compression stroke and instal the dial indicator where it fits snugly on the piston. In setting the tappet clearance, and after zeroing the dial indicator, turn slowly the crankshaft until the needle deflection stops and changes direction but record the maximum cam lobe lift. With the pistons at TDC on the compression stroke record this measurement and move each piston to TDC and do this for each valve. Having made these checks, it is recommended to cross-check them with such specifications; if camshaft lobe lift readings are below the specified values, it means that the camshaft is worn out and requires replacement. As for removal, a person shall disconnect the negative battery terminal, drain the cooling system and engine oil besides the removal of such components as the radiator, fan, drive belt, spark plug wires, ignition coil pack, alternator as well as the engine. On certain models, the following part are also to be detached, the oil pump drive gear, the camshaft position sensor, the intake manifold, the valve covers, the rocker arms, the push rods, valve lifters, the oil pan, the timing chain cover and the timing chain and sprockets. Probably, unscrew the camshaft thrust plate bolts and very gently, try to pull the camshaft out of the block without damaging the bearings. After removal clean and inspect the camshaft bearing journals for wear or damage, as described below Telescoping gauge and micrometer. If the journals are heavily worn or ovalised then one has no option but to overhaul the camshaft. If the lobes are not worn or unsightly, then the camshaft can be reused; otherwise, it is likely to be thrown away. Make sure that the oil ways are free from any debris than apply oil to the camshaft bearing journals and lobes with assembly lube and install the camshaft gently to avoid deforming the bearings. Place the thrust plate with lube and fasten the bolts in a correct torque; perform the process inversely to the removal process and fit the other camshaft position sensor if required.

Posted by FordPartsGiant Specialist