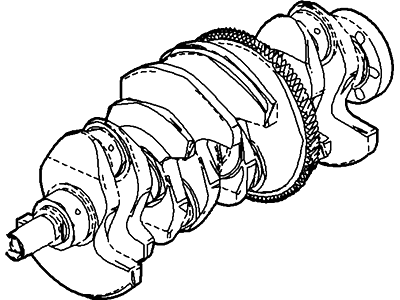

On the 2.3L and all 2005 engines, due to the fine tolerances in the bearing shells, no service operations are permitted on the cylinder block/crank assembly; in case of failure, the entire cylinder block, pistons, and crank assembly must be replaced as a unit, while the following procedures apply to earlier 2.0L engines. The crankshaft can only be removed after the engine/transaxle has been detached from the vehicle, assuming that the transaxle, flywheel/driveplate, liming bell, lower crankcase, cylinder head, oil pan, oil pump pick-up/strainer pipe, oil baffle, oil pump, and piston/connecting rod assemblies have been removed. Before removing the crankshaft, check the endplay by mounting a dial indicator with the probe aligned with the crankshaft and touching its end; push the crankshaft fully away from the gauge and zero it, then lever the crankshaft towards the gauge to check the reading obtained, which indicates the endplay. If the endplay exceeds specifications, inspect the crankshaft thrust surfaces for wear, and if no wear is found, new thrust washers should correct the endplay, noting that on some engines, the thrust washer/thrust control bearing is part of the Number 3 main bearing. If a dial gauge is unavailable, feeler gauges can be used by gently pushing the crankshaft towards the right-hand end of the engine and slipping feeler gauges between the crankshaft and the right-hand face of the Number 3 main bearing to determine clearance. Check the main bearing caps for markings indicating their locations, which should be numbered consecutively from the timing belt end of the engine; if not, mark them accordingly, and note the different fasteners used on caps 2 and 4. Loosen the cap bolts a quarter-turn at a time, starting with the left and right-hand end caps and working towards the center, until they can be removed by hand. Gently tap the caps with a soft-faced hammer to separate them from the cylinder block/crankcase, using the bolts as levers if necessary, and take care not to drop the bearing shells if they come out with the caps. Carefully lift the crankshaft out of the engine, ideally with assistance due to its weight, and with the bearings in place in the cylinder block/crankcase and main bearing caps, return the caps to their respective locations or install the lower crankcase, tightening the bolts finger-tight; leaving the old bearings in place until reassembly will help prevent accidental nicks or gouges in the bearing recesses, and new bearings should be used during reassembly.

Posted by FordPartsGiant Specialist