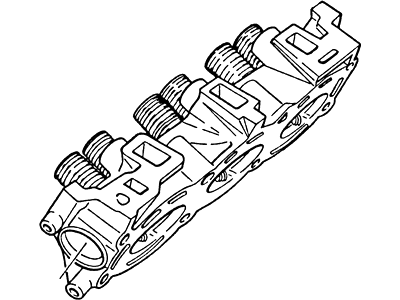

This operation can only be done if the engine has cooled down; it cannot be done while the engine is still running. If carbureted models are to be removed, the connection from the negative terminal of the battery has to be disconnected. If the left cylinder head is being removed on a vehicle with a compressor air conditioning system, remove the compressor and suspend this away to the side of the engine compartment. When the car has a power steering, the power steering bracket retaining bolt, from the left cylinder head should be removed, in addition the position of the power steering pump should be adjusted to ensure that it does not drip fluid, and if there is no provision, fabricate one. If the right cylinder head is being removed, remove the through-bolt at the back of the alternator mounting bracket. Take off inlet tube of air cleaner on right side cylinder head in the event it is fitted and also detach the ground wire behind the cylinder head. In the EFI models, also lose the connection of the cable from the negative terminal of the battery. As with the removal of the left cylinder head, a/c compressor/power steering bracket located at the front side of the engine; other accessories and, if required, the compressor must be detached from the bracket. Further, take out the oil dipstick and tube assembly and, if existent, the speed control bracket. For the right cylinder head, the alternator wiring harness and air pump hoses and the alternator/air pump bracket at the front of the engine with accessories, must be detached. In all the models, there is need to avail the intake manifold, the valve cover(s) the rocker arms and the pushrods as well as the exhaust manifold(s). If fitted remove the thermactor air supply tubes from the rear of head. Unwind the cylinder head retaining bolts crosswise starting from the final pattern you used to tighten them, then remove the bolts, making a point of arranging these in order depending on where they will be reinstalled. With the help of hoist or an assistant, the cylinder head should be removed from the block without damaging the gasket surfaces. Check it if required and see the condition of the cylinder head and its parts, and make sure the cylinder head block is in level with the block deck. At installation make sure that the cylinder head and the engine block surfaces in contact with the cylinder head gasket should be clean and flat to accommodate the new gasket. Stage the head gasket over the dowel pins on the block with the intake side facing the right direction. If the cylinder head is too heavy you may need help to ease the cylinder head onto the block, don't drag it across the block or move it sideways as this will cause scratch to the block. First well lubricate the cylinder head retaining bolts, then screw on the head into the engine block. Loosen the nuts eccentrically in a sequence; then, finally or in two or three stages, tighten them to the torque. The rest of the installation procedure is pretty much the opposite of the removal process. Begin with cranking the engine and search for leakages and weird or unusual sound and so forth, we check and often set the ignition timing to the right position.

Posted by FordPartsGiant Specialist