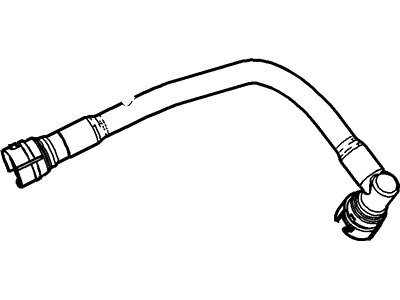

High temperatures under the hood can cause deterioration of the rubber and plastic hoses used for engine, accessory, and emission systems operation. Periodic inspections should be made for cracks, loose clamps, material hardening, and leaks. Most hoses are secured to the fittings with clamps. Where clamps are used, check to be sure they haven't lost their tension, allowing the hose to leak. If clamps aren't used, make sure the hose has not expanded or hardened where it slips over the fitting, allowing it to leak. To reduce hydrocarbon emissions, crankcase blow-by gas is vented through the PCV valve (V6 models only) in the valve cover to the intake manifold via a rubber hose on most models. The blow-by gases mix with incoming air in the intake manifold before being burned in the combustion chambers. Check the PCV hose for cracks, leaks, and other damage. Disconnect it from the valve cover and the intake manifold and check the inside for obstructions. If it's clogged, clean it out with solvent. It's quite common for vacuum hoses, especially those in the emissions system, to be color-coded or identified by colored stripes molded into them. Various systems require hoses with different wall thickness, collapse resistance, and temperature resistance. When replacing hoses, be sure the new ones are made of the same material. Often the only effective way to check a hose is to remove it completely from the vehicle. If more than one hose is removed, be sure to label the hoses and fittings to ensure correct installation. When checking vacuum hoses, be sure to include any plastic T-fittings in the check. Inspect the fittings for cracks and the hose where it fits over each fitting for distortion, which could cause leakage. A small piece of vacuum hose (1/4-inch inside diameter) can be used as a stethoscope to detect vacuum leaks. Hold one end of the hose to your ear and probe around vacuum hoses and fittings, listening for the "hissing" sound characteristic of a vacuum leak. The fuel lines are usually under pressure, so if any fuel lines are to be disconnected, be prepared to catch spilled fuel. Check all flexible fuel lines for deterioration and chafing. Check especially for cracks in areas where the hose bends and just before fittings, such as where a hose attaches to the fuel pump, fuel filter, and fuel injection unit. When replacing a hose, use only hose that is specifically designed for your fuel injection system. Spring-type clamps are sometimes used on fuel return or vapor lines. These clamps often lose their tension over a period of time and can be "sprung" during removal. Replace all spring-type clamps with screw clamps whenever a hose is replaced. Some fuel lines use spring-lock type couplings, which require a special tool to disconnect. Sections of metal line are often used for fuel lines between the fuel pump and the fuel injection unit. Check carefully to make sure the line isn't bent, crimped, or cracked. If a section of metal fuel line must be replaced, use seamless steel tubing only, since copper and aluminum tubing do not have the strength necessary to withstand vibration caused by the engine. Check the metal brake lines where they enter the master cylinder and brake proportioning unit (if used) for cracks in the lines and loose fittings. Any sign of brake fluid leakage calls for an immediate thorough inspection of the brake system.

Posted by FordPartsGiant Specialist