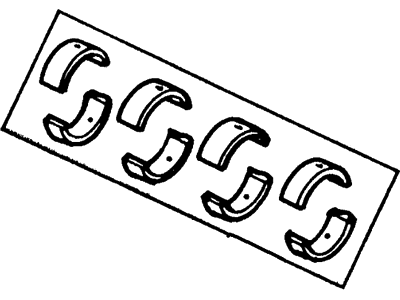

To ensure reliability, purchase Ford part # C2OZ-6211-R Bearing - Connecting Rod. It is sometimes referred to as Lincoln Rod Bearing. In terms of quality and longevity, OEM parts are top-tier. This is because they are made according to Ford's demanding factory specifications and go through strict quality control. This part fits specific Lincoln Continental, Mark VI, Mark VII models.

FordPartsGiant.com is a leading supplier of genuine Ford parts and accessories such as Ford C2OZ6211R Bearing - Connecting Rod. On our platform, we provide genuine Ford parts at incredible prices while ensuring top-tier quality. Feel at ease shopping with us, knowing our parts have a hassle-free return policy and rapid delivery service. For detailed Lincoln parts information, click here.