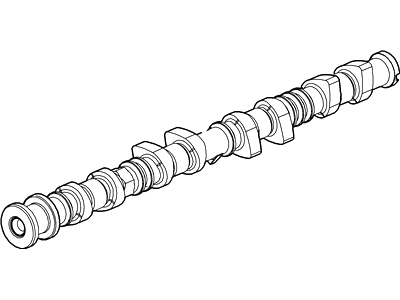

Every time the camshafts are to be removed for some procedure, it is prudent to check on the valve clearances prior to disassembly in order to order for new lifters if need be, from the dealership. For removal, on 1.5L and 1.6L engines, timing belt must be removed, on 2.0L, 2.3L and 2.5L engines, the timing chain has to be removed. Before the timing chain is to be removed observe the positions of the no 1 cylinder cam lobes and the slots in the end of the camshafts for the tool. Remove camshaft phaser bolt caps, phaser bolts, phasers and sprockets with an Allen head socket, and plan to mark them using indelible ink if they will need to be reinstalled. On 2.0L and 2.5L models: The variable camshaft timing solenoid fasteners and the solenoids will have to be extracted from the front camshaft bearing cap. For both 1.5L and 1.6L vehicles, remove the camshaft earnest very gently for you loosen the bore or the sealing sites of the cylinder head. Loosen and take out the bolts of front one-piece camshaft bearing cap and raise it off both camshafts noting the positions and orientation of the bearing caps. Rather turn the camshaft bearing cap bolts an equal amount at a time in a clockwise direction to reduce loads of the valve springs progressively and then with care, withdraw the caps and if marked, ensure that there are locating dowels before pulling out the camshafts. Employ sixteen small and clean small vessels that will serve to store each of the lifters in order to avoid interchangeability. Visually check the camshafts and lifters for any signs of wear and measure them using a micrometer outside and inside thickness and look for a great difference that may require change. If the parts of the engine that deals with the valves are noisy, this may indicate that the valve clearances are out and this is done as part of the engine's maintenance. On the camshaft lobes look for any sign of wear or overheating and bearing journals cylinder head bearing surfaces for any sign of wear or pitting. Take the caliper and measure the diameter of each journal in at least three points and if the diameter is below the allowed values then replace the camshaft. To ensure the clearances of the bearing journals are as required, all bearing surfaces must be free from debris, the camshafts and bearing caps must be fitted in place with Plastigage across each journal, tighten the bolts to the recommended torque, and this will be followed by measuring the width of the compressed strands of the Plastigage. If any bearing clearance is beyond service limits, replace the camshaft and again check the above said clearance. With regard to camshaft end play, remove any dirt on the bearing surfaces, fit the camshafts together with the bearing caps, tighten the bolts and using a dial indicator, determine the amount of end play. If the endplay is more than the limit specified for a service, then change the camshaft and check it again. For installation, ensure that the crank shaft is at TDC also do check that the timing pin is in its correct position. If new parts have been fitted, check the valve clearances, aligning the mark on the crankshaft with the 12 o'clock position, and removing any special tools, before rotating the crankshaft a further 270 degrees clockwise. Insert the lifters on the cylinder head bores, fit the camshafts and further snug down all the camshaft bearing caps starting from the No.1 position. Procedure to check the valve clearance: Rotate only the camshafts after which the caps would have to be loosened in order to relieve the tension and then make the necessary correction. Once in position, bring the crankshaft home to the timing pin to make sure it aligns and comes in contact with it. A cylinder head lifter bores/and or lifters may be tripped on the block, then oiled before carefully putting in place to ensure that each lifter is replaced in its bore. Lubricate the camshaft bearing surfaces and fit the camshaft bearing caps with consideration to their original positions. Torque the camshaft bearing cap bolts sixy passing bolt in a sequence until the each cap touches the cylinder head, and continue with the rest of the procedures. For 1.5L and 1.6L models, insert the camshaft seals perpendicular and into the cylinder head, followed by the sprockets and phaser, then the retaining bolts, but loosely only. Finish the reassembly process of the camshaft sprockets and timing belt for the 1.5L & 1.6L vehicles, while for the 2.0L, 2.3L & 2.5L vehicles set the valve clearance before putting the valve cover.

Posted by FordPartsGiant Specialist