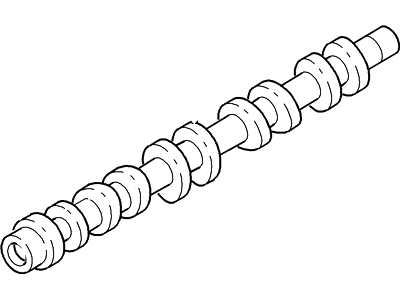

To verify camshaft lobe lift and to know how much is worn, one has to do the following; Firstly, remove the valve covers. Place the first piston at TDC on the compression stroke and put a dial indicator on the cylinder head; the plunger of this indicator must seat onto the first rocker arm. Retrace the amount on the dial indicator and rotate the crankshaft in the normal direction until the dial stop, when the needle of the indicator starts moving in the opposite direction, then the maximum cam lobe lift will be noted. This measurement should also be recorded and the piston moved back to the TDC position, the dial indicator moved to the remaining number one cylinder pushrod for the other result of each valve to be recorded. Repeat this for the other valves which, when are properly aligned all pistons should be on the compression stroke and in line with the firing order. Upon doing the checks, make the comparison with the specifications; in the case of camshaft lobe lift being lower than the specified value, this is an indication of wear and hence the need for a new camshaft. For dismantling, properly withdrew the pushrods, valve lifters, timing chain, and camshaft sprocket, and the radiator too is to be removed. Measure the camshaft endplay with a dial indicator; if it measures more than standard, replace the thrust plate each time you reinstall it. Take out the camshaft thrust plate bolts and then using a long bolt you will withdraw the cam from the block without straining the bearings. Post removal, be sure to wash and examine the bearing journals for wear or harm; if harmed, both camshaft and bearings will need replacement-they are tricky to replace without the help of an expert. Check for wear by measuring the bearing journals and analyse the camshaft lobes for any discoloration or damages; if none they camshaft can be reused. For the bearing replacement, tools and skills are required, thus, it is advisable to take the block to an automotive machine shop. In the case of the camshaft, one must coat the bearing journals and lobes with assembly grease, than push the camshaft into position, and apply grease to the thrust plate before final tightening down. Failure of these goes in the reverse order of their removal when you are reinstalling the lifters and the pushrods before the rocker arms, the timing chain, and finally the valve covers. Last but not the least, replace the engine oil and also fit in a new oil filter before turning on the engine.

Posted by FordPartsGiant Specialist