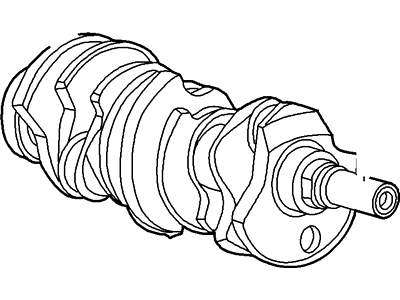

To ensure reliability, purchase part # F7DZ-6303-AA Crankshaft Assembly. It is also called Crankshaft. OEM parts are of high quality and known for their longevity. This is because they are built to the Ford standards which are relatively high and undergo rigorous quality control testing. This part fits specific Lincoln LS, MKZ models.

FordPartsGiant.com is a leading supplier of genuine components and accessories such as F7DZ6303AA Crankshaft Assembly. Looking to purchase quality low-cost OEM Ford parts? You have just found the right place. For detailed Lincoln parts information, click here.