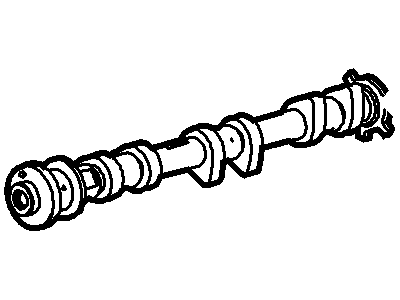

When unbolting the rear bank cylinder head of the 3.0L V6 engine, the timing chain of the rear cylinder bank should be disconnected, and the position of each camshaft cap should be noted, and the caps should be marked if necessary to avoid confusing them. Slowly and equally undo the camshaft bearing cap bolts from the order in which the caps were tightened, and pull off the caps, slightly striking them if possible. Camshaft bearing cap and cylinder heads should be replaced at their original positions. When removing the intake and exhaust camshafts, use a marker to place reference points that will allow you to put them in the same positions during the assembling phase of the work and the same goes for the rocker arms that should be placed in a suitable container. Remove the hydraulic lash adjusters from their bores, ensure that you arrange them for reuse later. In the case of the front bank, rotate the crankshaft so that the keyway is at the 11 o'clock position, remove the timing chain, the water pump pulley, and as in the case of removing all the front camshafts, rocker arms, as well as lash adjusters. Each of the hydraulic lash adjusters must be checked for wear and to ensure there is no tapering of the diameters. Check rocker arms for cracks and camshaft lobes for wear; measure camshaft bearing journals for wear. For oil clearance check, cleaning of bearing surfaces, fitting of camshaft with plastigage and measurement of flattened width of plastigage only. Any bearing clearance which has gone beyond the specified tolerances must be corrected with the replacement of the camshaft or the cylinder head if required. To install, applying oil on the rocker arms, hydraulic lash adjusters and camshafts and placing it to its original position, tighten the bearing cap at the specified torque first at the upper then at the lower camshaft. Replace the timing chain and cover and put oil into the crankcase and check if there is any oil leak after connecting the battery. The 3.5L V6 engine requires special camshaft holding tools. Every timing chain and VCT assemblies should be deleted with the camshaft cap position An erector seat should also be used to lift the camshafts from the cylinder head. Lifters should be checked for wear and tear and should deb ideally able to operate smoothly. Reinstall lifters, correct any valve-lifter clearances that are required while lubricating them. For 2012 and earlier models, camshafts and bearing caps should be lubricated and fitted and the valve clearance checked once more. For camshafts updates to secures and for all 2013 and later models, with new seals in the grooves of the camshafts, lubricate the bearing journals and its position which should be followed in putting the bearing caps. Recheck the valve clearances, needing to rotate camshaft for the VCT unit putting back, and then assemble, with putting back of the primary timing chain and oil tubes, make sure that all the steps are in reverse order. It is advisable to fill the cooling system, change the oil and put on a new oil filter before turning on the engine.

Posted by FordPartsGiant Specialist