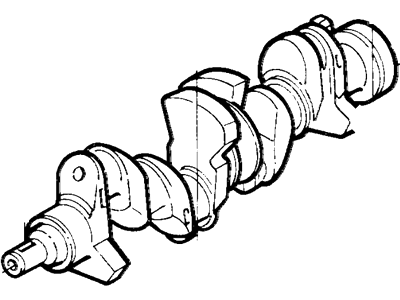

The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that the flywheel or driveplate, front crankshaft pulley, timing chain and sprockets, oil pan, oil pump, and piston/connecting rod assemblies have already been detached. First, check the endplay by mounting a dial indicator with the stem aligned and just touching one of the crank throws. Push the crankshaft to the rear and zero the dial indicator, then pry it to the front and note the reading; the movement indicates the endplay. If it exceeds specifications, inspect the crankshaft thrust surfaces for wear, and if no wear is found, a new thrust bearing may resolve the issue. For endplay less than the minimum, examine the thrust bearing surfaces for scratches, burrs, nicks, and dirt. If a dial indicator is unavailable, feeler gauges can be used by prying or pushing the crankshaft to the front and slipping the gauges between the crankshaft and the thrust main bearing to measure clearance. The thrust bearing is located in the number 5 bearing saddle on 4.9L engines and in the number three bearing saddle on V6 and V8 engines. Check the main bearing caps for markings indicating their locations, which should be numbered consecutively from front to rear; if not, mark them using number stamping dies or a center-punch, ensuring to make the punch marks near one of the bolt heads. Loosen the main bearing cap bolts gradually until they can be removed by hand, then gently tap the caps with a soft-face hammer to separate them from the engine block, using the bolts as levers if necessary while avoiding dropping the bearing inserts. Carefully lift the crankshaft out of the engine, ideally with assistance due to its weight, and with the bearing inserts in place, return the caps to their original locations on the block and tighten the bolts finger tight. Finally, remove the Woodruff key from the crankshaft nose to prevent loss, or leave it in place if difficult to remove.

Posted by FordPartsGiant Specialist