My Garage

My Account

Cart

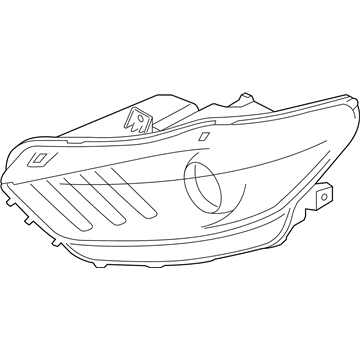

Genuine Ford Mustang Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Headlights found

Ford Mustang Lamp Assembly

Part Number: FR3Z-13008-J$1136.90 MSRP: $1303.79You Save: $166.89 (13%)Ships in 1-3 Business DaysFord Mustang Bulb - Tungsten

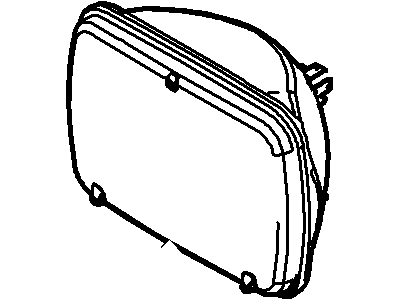

Part Number: F3UZ-13007-A$48.39 MSRP: $76.07You Save: $27.68 (37%)Ships in 1 Business DayFord Mustang Headlamp Assembly

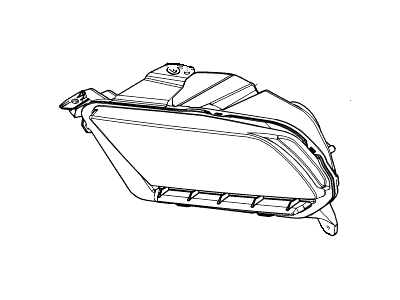

Part Number: AR3Z-13008-B$119.32 MSRP: $174.45You Save: $55.13 (32%)Ships in 1-3 Business DaysFord Mustang Lamp Assembly

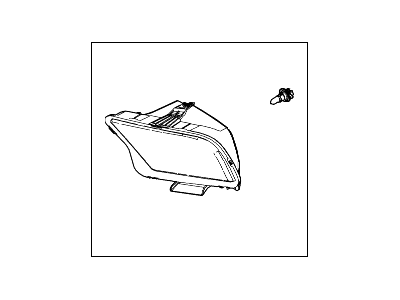

Part Number: FR3Z-13008-JCP$803.13 MSRP: $1303.78You Save: $500.65 (39%)Ships in 1 Business DayFord Mustang Lamp Assembly

Part Number: FR3Z-13008-K$1118.24 MSRP: $1337.61You Save: $219.37 (17%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: 7R3Z-13008-A$338.16 MSRP: $498.77You Save: $160.61 (33%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: 7R3Z-13008-B$343.35 MSRP: $506.42You Save: $163.07 (33%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: AR3Z-13008-C$137.45 MSRP: $200.95You Save: $63.50 (32%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: 7R3Z-13008-C$92.34 MSRP: $135.00You Save: $42.66 (32%)Ships in 1-2 Business DaysFord Mustang Headlamp Assembly

Part Number: AR3Z-13008-A$122.57 MSRP: $179.20You Save: $56.63 (32%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: AR3Z-13008-D$137.45 MSRP: $200.95You Save: $63.50 (32%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-C$833.27 MSRP: $1328.98You Save: $495.71 (38%)Ships in 1-2 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-E$652.92 MSRP: $1041.33You Save: $388.41 (38%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-D$849.22 MSRP: $1328.98You Save: $479.76 (37%)Ships in 1-2 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-F$665.41 MSRP: $1041.33You Save: $375.92 (37%)Ships in 1-3 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-A$834.67 MSRP: $1276.25You Save: $441.58 (35%)Ships in 1-2 Business DaysFord Mustang Headlamp Assembly

Part Number: JR3Z-13008-B$857.64 MSRP: $1276.25You Save: $418.61 (33%)Ships in 1-2 Business DaysFord Mustang Headlamp Assembly

Part Number: DR3Z-13008-CCP$652.36 MSRP: $1059.02You Save: $406.66 (39%)

| Page 1 of 3 |Next >

1-20 of 59 Results

Ford Mustang Headlight

The other part of the exterior of the Ford Mustang is also important for visibility while driving especially at night is the headlights. Since its inception, Mustang headlights have gone through six generations, and several configurations concerning the style and type of light they use ranging from halogen to LED. Such developments provide broader lighting and a better light assembly offering solutions such as dullness and flickering, that might jeopardize safety. Mustang headlights have to be replaced anytime they get rusty or are unable to light properly since it may start being dangerous whenever on the road and may even break traffic rules. Regardless of going for standard production or having tailored headlights, it is advised to find well built and fitted products that are also sectional to legal requirements. In a nutshell, the Ford Mustang's headlights are very important for the vehicle's dynamics and the car's exterior.

We provide a wide range of Ford Mustang Headlight at the best prices possible. If you need Ford Mustang Headlight, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Mustang Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to ensure safety and visibility on Ford Mustang?A:The headlights must be aimed correctly to avoid blinding oncoming drivers, which can lead to serious accidents or impair visibility. It is important to check the aim every 12 months and whenever a new headlight housing is installed or front-end bodywork is done. The following procedure provides a temporary adjustment until a professional can perform a proper alignment. Vehicles have a vertical adjustment screw on the back of the headlight housing, and adjustments should be made on a level surface with a full gas tank and normal load. A simple method involves using masking tape, a blank wall, and a level floor. First, position masking tape vertically on the wall to mark the vehicle centerline and the centerline of each Headlight Bulb, then add a horizontal tape line in relation to the headlight centerlines, which may be easier with the vehicle parked a few inches away. The vehicle should be parked 25 feet from the wall, level, with a half-full gas tank and no heavy load. Adjust the high intensity zone to be two inches below the horizontal line and two inches to the side of the headlight vertical line, away from oncoming traffic, by turning the adjusting screw to move the beam up or down. The high beams will adjust automatically with the low beam. It is advisable to have the headlights properly adjusted by a dealer service department or service station as soon as possible.

Related Ford Mustang Parts

Browse by Year

2024 Headlight 2023 Headlight 2022 Headlight 2021 Headlight 2020 Headlight 2019 Headlight 2018 Headlight 2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight 1992 Headlight 1991 Headlight 1990 Headlight 1989 Headlight 1988 Headlight 1987 Headlight 1986 Headlight 1985 Headlight 1984 Headlight 1983 Headlight 1982 Headlight 1981 Headlight 1980 Headlight