My Garage

My Account

Cart

Genuine Mercury Mariner Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

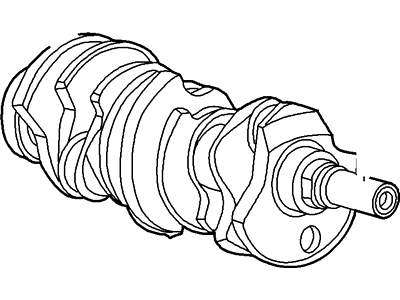

Mercury Mariner Crankshaft Assembly

Part Number: F7DZ-6303-AA$294.59 MSRP: $434.50You Save: $139.91 (33%)Ships in 1-3 Business Days

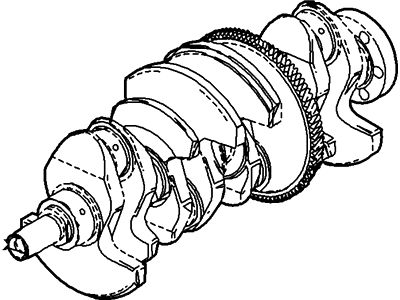

Mercury Mariner Crankshaft

We provide a wide range of Mercury Mariner Crankshaft at the best prices possible. If you need Mercury Mariner Crankshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Mercury Mariner Crankshaft Parts Questions & Experts Answers

- Q: How is the crankshaft removed and installed on Mercury Mariner?A:The crankshaft can only be removed after the engine is pulled out of the car, under condition that the flywheel, crankshaft pulley, timing belt, oil pan, oil pump body, oil filter, and piston/connecting rod assemblies have been removed. To check the crankshaft end-float, the dial-indicator is attached to the crankshaft as shown before the removal of the crankshaft. Insert the indicating pin beneath the crankshaft, grate the indicator to the rear until it comes to zero, then grate it to the front and the reading should range from 0.003 to 0.010 inch (0.076 to 0.254 mm). If a dialindicator is not available, clearance may be checked with a feeler gauges. Ease off the main bearing cap or lower cylinder block bolts sufficiently so that they can be undone with the nut wrench and said process ought to be done in the method mentioned above. In the case of four-cylinder engines, the main bearing caps have to be unbolted; in the case of V6 engines, try to give the lower cylinder block a gentle knock with a soft-face hammer and it can be lifted off. Slowly lift out the crankshaft as it can be very heavy and is easier done with another person, then torque the main bearing caps or screw the lower cylinder block back in only hand tight. The engine block and crankshaft have to be clean and inspected when the installation is carried out. Pull off the main bearing caps, clean the bearing surface and place new upper main bearing on the engine block in a proviso that the oil holes are matching. Clean the lower main bearing inserts and fit the lower main caps. They should not be 'hammered' into place and the metal should not be lubricated at this stage. Scrape and remove sand and dirtiest from crankshaft main bearing journals and oil holes. Place the crankshaft on the main bearings and then measure the main bearing oil clearance with the help of Plastigage and do not interchange the two. The caps or the lower cylinder block should be fitted without disturbing the Plastigage and smeared the bolt threads with clean engine oil: tighten the nuts and bolts-through the sequence and without turning the crankshaft. Regrettably, having removed the caps, and attempted to measure the Plastigage width against the scale to determine oil clearance, the width of the Plastigage had doubled (from 4mm to 8mm) due to the interference of dirt or oil. In case clearance is wrong, then measure and compare bearing insert size and look for taper on the crank journal. When the layer of Plastigage has been removed clean both faces of the bearing insert and coat with a light film of grease or assembly lube before replacing the crankshaft. Remove the bearing insert from the housing and clean the faces where it will contact with lubricant leaving the oil free surface. For V6 engines use RTV for the lower cylinder block of the engine block, while for the four-cylinder engines place main bearing caps in the forward position with arrows. Use clean engine oil on threads of bolts and then screw the bolts to fit by hand then torque them in the right order. Check crankshaft end play again and turn the crankshaft to and fro with your fingers and make sure it does not bind, only spins free. Last of all, fit a new rear main oil seal.