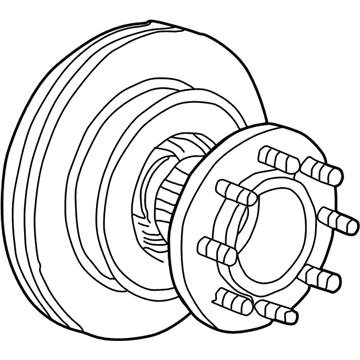

Loosen the wheel lug nuts, raise the vehicle, and support it securely on jackstands while applying the parking brake, then remove the wheels. Visually inspect the disc surface for score marks and other damage, noting that light scratches and shallow grooves are normal, but deep grooves require disc removal and refinishing by an automotive machine shop; check both sides of the disc. To check disc runout, place a dial indicator about 1/2-inch from the outer edge of the disc, and if checking a front or rear disc on a 4WD model with single rear wheels, install the lug nuts with flat sides facing in and tighten them securely to hold the disc in place, then set the indicator to zero and turn the disc, ensuring the reading does not exceed the runout limit, as exceeding it necessitates refinishing. The disc must not be machined to a thickness less than the specified minimum thickness, which is cast into the disc, and thickness can be checked with a micrometer at several points. Remove the brake calipers without disconnecting the brake hoses and hang them out of the way, then remove the caliper mounting bracket retained by two bolts. For 2WD model front discs, remove the grease cap, wheel bearing retainer nut, spindle nut, outer bearing retainer washer, and outer wheel bearing, then remove the disc/hub. For a front disc on a 4WD model with single rear wheels, remove the lug nuts and pull the disc off the hub; for a truck with dual rear wheels, remove the hub extender bolts and detach the hub extender before removing the disc. For a rear disc on a dual rear wheel axle, remove the hub assembly from the rear axle and unbolt the disc from the hub, while on single rear wheel axles, the disc can be slid off the wheel studs. Installation is the reverse of removal, and on models so equipped, tighten the disc-to-hub bolts to the specified torque before lowering the vehicle and tightening the wheel lug nuts to the appropriate torque.

Posted by FordPartsGiant Specialist