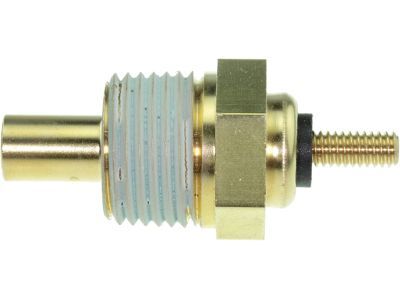

The engine coolant temperature sensor is a thermistor that varies its voltage output based on temperature changes. Resistance values decrease as the sensor temperature increases and vice versa. Failure in the coolant sensor circuit triggers codes 21, 51, or 61 (two-digit) or 116, 117, 118 (three-digit). Resistance values should be checked while cold (58,750 to 40,500 ohms) and at operating temperature (3,600 to 1,840 ohms). Signal voltage to the sensor from the PCM should be around 5.0 volts. During replacement, wait for the engine to cool, use Teflon tape on threads, and handle the sensor with care.The Manifold Absolute Pressure (MAP) sensor monitors intake manifold pressure changes, converting them into a voltage output. A failure triggers codes 22 or 72 (two-digit) or 126, 128, 129 (three-digit). Check reference voltage (4.0 to 6.0 volts), backprobe the MAP/BP Signal wire, and apply vacuum to observe tachometer readings. Incorrect results indicate MAP sensor replacement.Oxygen sensors monitor exhaust oxygen content, adjusting air/fuel mixture. Check for a steady signal voltage between 0.35 and 0.55 volts at normal operating temperature. Codes 41, 42, 91, 92 (two-digit) or 136, 137, 139, 144, 171-178 (three-digit) indicate issues. Ensure the oxygen sensor heater receives battery voltage. Special care during service is essential.The Throttle Position Sensor (TPS) monitors throttle angle. Check for proper signal voltage (0.50 to 1.0 volts at idle, 4.0 to 5.0 volts at full throttle) and reference voltage (approximately 5.0 volts). Check potentiometer resistance (0.8 to 1.0 K ohms at closed throttle, 3.0 to 4.0 K ohms at full throttle). Replace if readings are incorrect.The Mass Air Flow (MAF) sensor, for 4.6L engines, measures air entering the engine. Check for power, signal voltage (0.2 to 1.5 volts at idle, increasing to about 2.0 volts at 60 mph), and use an ohmmeter for resistance checks. Replacement involves disconnecting the electrical connector, removing the air cleaner assembly, and uninstalling the MAF sensor.The Manual Lever Position (MLP) sensor, now Transmission Range (TR) sensor, indicates transmission gear. Check terminal connectors for attachment, verify power, and adjust if necessary. Diagnostics require special tools.The air conditioning clutch control involves PCM control of the compressor clutch. If the air conditioning does not function, check relays and switches. To test, remove the relay and bridge the battery feed and compressor clutch terminals. The Vehicle Speed Sensor (VSS) monitors speed, usually setting Code 24 if faulty. Check for signal voltage (10 volts or more). Replacement involves disconnecting the electrical connector, removing the retaining bolt, and lifting the VSS from the transmission. The Intake Manifold Temperature Sensor measures air temperature entering the engine. Check for correct reference voltage (5 volts) and resistance changes with temperature. Code 54 indicates issues.The power steering pressure switch affects idle quality. Problems may set Code 52. Check for open or closed circuits affecting engine timing.The crankshaft position sensor defines engine position for the PCM, and any issues require professional diagnosis. Replacement involves removing the electrical connector and retaining bolt.The camshaft position sensor is triggered by the camshaft sprocket's high point. Diagnostic work should be done by professionals.The Brake Light Switch informs the PCM when brakes are applied. Ensure proper voltage and continuity, and replace if needed. Brake light circuit and bulb conditions can impact idle quality.

Posted by FordPartsGiant Specialist