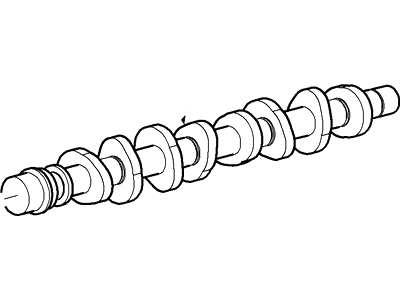

To check cam lobe wear, remove valve covers and position number one piston at TDC on compression stroke. Mount dial indicator on engine, align with first rocker arm, zero indicator, and slowly turn crankshaft to determine max cam lobe lift. Record figures for each valve by repeating process across cylinders. Compare results to specifications, and if lift is less than specified, replace camshaft. For removal, remove pushrods, valve lifters, timing chain, camshaft sprocket, and radiator. Check camshaft endplay, replace thrust plate if necessary, and remove camshaft using long bolt. Inspect camshaft for wear, pitting, and seizure. Measure bearing journals for wear or out-of-round conditions, and check camshaft lobes for discoloration, score marks, or chipping. If lobes are in good condition and measurements are within spec, camshaft can be reused. If bearing replacement is required, use special tools and follow instructions for removal and installation. Lubricate camshaft and bearing journals with engine assembly grease, then carefully slide camshaft into engine. Apply moly-base grease or assembly lube to both sides of thrust plate and install on block. Tighten bolts, and follow appropriate sections to reinstall lifters, pushrods, rocker arms, timing chain/sprocket, timing chain cover, and valve covers. Complete remaining installation steps in reverse order, change oil, and install new oil filter before starting engine.

Posted by FordPartsGiant Specialist