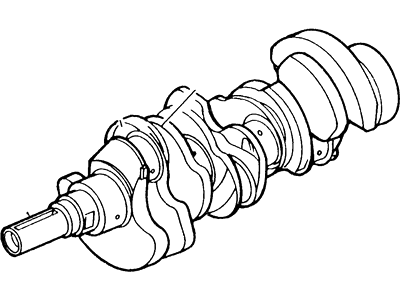

Crankshaft installation is the first task in engine reassembly, assuming the engine block and crankshaft have been cleaned, inspected, and repaired. Position the engine with the bottom facing up, then remove the main bearing cap bolts and lift out the caps, laying them out in order for correct installation. If present, remove the original bearing inserts from the block and caps, ensuring the bearing surfaces are kept spotlessly clean. Clean the back sides of the new main bearing inserts and place one in each main bearing saddle in the block, ensuring the grooved insert is installed correctly. Lay the corresponding bearing from each set in the main bearing cap, ensuring the tab fits into the recess and that the oil holes align. The flanged thrust bearing must be installed in the third cap and saddle. Clean the bearing faces and crankshaft main bearing journals, checking or cleaning the oil holes in the crankshaft. Once the crankshaft is clean, lay it in position in the main bearings and check the main bearing oil clearance using Plastigage, placing it on each crankshaft main bearing journal. Clean the bearing faces in the caps and install them in their respective positions without mixing them up, tightening the main bearing cap bolts in three steps to the specified torque without rotating the crankshaft. After removing the bolts and caps, compare the width of the crushed Plastigage to the scale to obtain the main bearing oil clearance, ensuring it meets specifications. If the clearance is incorrect, check for dirt or oil interference before considering different bearing inserts. Carefully scrape off any Plastigage material from the main bearing journals and bearing faces. Lift the crankshaft out, clean the bearing faces in the block, and apply a thin layer of moly-base grease or engine assembly lube to each bearing surface, including the thrust faces. Ensure the crankshaft journals are clean before laying the crankshaft back in place, then clean the bearing faces in the caps and apply lubricant. Install the caps with arrows pointing toward the front of the engine, applying sealant where necessary, and install the bolts. Tighten all bolts except the thrust bearing cap bolts to the specified torque, then tighten the thrust bearing cap bolts to 10-to-12 ft-lbs. Tap the ends of the crankshaft to align the thrust surfaces, retightening all main bearing cap bolts to the specified torque while installing the rear main bearing oil seal. For manual transmission models, install a new pilot bearing in the crankshaft, then rotate the crankshaft by hand to check for binding. Finally, check the crankshaft endplay with a feeler gauge or dial indicator, ensuring it is correct if the thrust faces are not worn or damaged and new bearings are installed.

Posted by FordPartsGiant Specialist