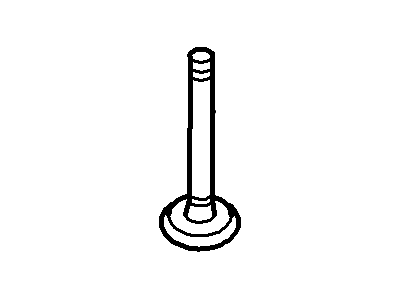

To ensure reliability, purchase Ford part # 7T4Z-6507-B Valve - Inlet. It is sometimes referred to as Mercury Intake Valve. In terms of quality and longevity, OEM parts are top-tier. This is because they are made according to Ford's demanding factory specifications and go through strict quality control. This part fits specific Mercury Milan, Sable models.

FordPartsGiant.com is a leading supplier of genuine Ford parts and accessories such as Ford 7T4Z6507B Valve - Inlet. On our platform, we provide genuine Ford parts at incredible prices while ensuring top-tier quality. Feel at ease shopping with us, knowing our parts have a hassle-free return policy and rapid delivery service. For detailed Mercury parts information, click here.