×

- Live Chat

- 1-888-788-9341

My Garage

My Account

Cart

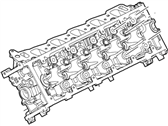

Genuine Ford Excursion Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Cylinder Heads found

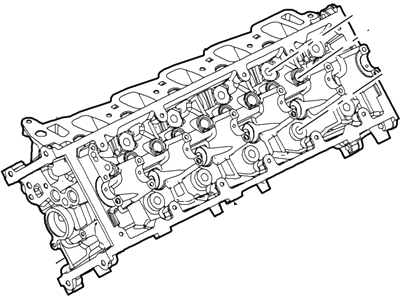

Ford Excursion Cylinder Head Assembly

Part Number: F6TZ-6049-ARM$877.66 MSRP: $1111.43You Save: $233.77 (22%)Ships in 1-3 Business DaysFord Excursion Cylinder Head Assembly

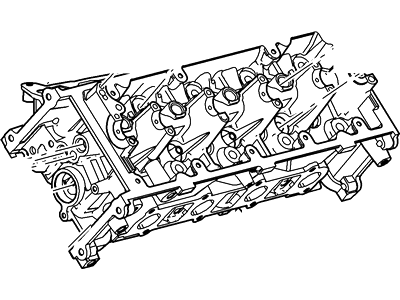

Part Number: 2C3Z-6049-AA$3458.21 MSRP: $4743.08You Save: $1284.87 (28%)Ships in 1-3 Business DaysFord Excursion Kit

Part Number: 3C3Z-6049-CARM$950.53 MSRP: $1406.67You Save: $456.14 (33%)Ships in 1-2 Business DaysFord Excursion Cylinder Head Assembly

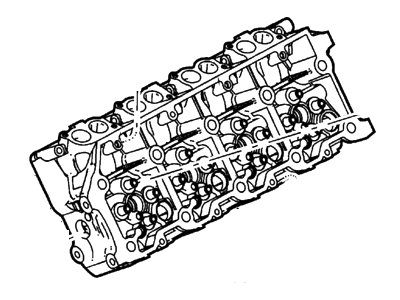

Part Number: 2C2Z-6049-AA$3458.21 MSRP: $4743.08You Save: $1284.87 (28%)Ships in 1-3 Business DaysFord Excursion Cylinder Head Assembly

Part Number: 2C2Z-6049-BA$3219.65 MSRP: $4415.38You Save: $1195.73 (28%)Ships in 1-3 Business DaysFord Excursion Cylinder Head Assembly

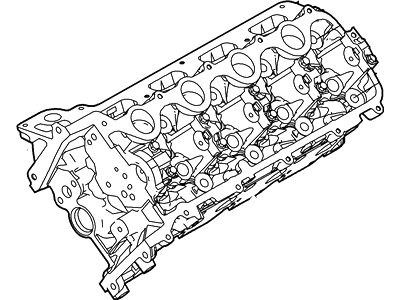

Part Number: 2L1Z-6049-DA$801.57 MSRP: $1093.85You Save: $292.28 (27%)Ships in 1-3 Business Days

Ford Excursion Cylinder Head

We provide a wide range of Ford Excursion Cylinder Head at the best prices possible. If you need Ford Excursion Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Excursion Cylinder Head Parts Questions & Experts Answers

- Q: What precautions should be taken when removing and installing cylinder heads in gasoline engine on Ford Excursion?A: Cylinder heads must be removed when the engine is absolutely cold to avoid warpage of the metal. This was not the easiest job, or the most straightforward, because in order to remove the cylinder head, one has to use special tools and equipment, and all these have to be gathered in advance. For the 2003 and later models, it is recommended that the engine be pulled and then placed on an engine stand; it is also recommended that a new rear main seal be installed at this time. Still, start with handicapping the negative battery terminal, evacuating the engine oil and cooling system, and eradicating the valve covers, Timing Chain, cover, chains, tensioners, and guides. In the case of a V10 engine, where the left cylinder head has been replaced, the balance shaft has to be also removed. Third, disconnect the intake and Exhaust Manifolds, although in some cases it might be faster to undo the exhaust pipes from the manifolds, while they remain connected to the heads. If only changing the head gaskets the Camshafts, rocker arms, and the lash adjuster can remain in place while the cylinder heads are removed but if overhauling heads then the rocker arms, and camshafts must come off first. Tighten the center nut in a crankshaft to loosen the cylinder-head bolts, and apply a breaker bar; employ a pry bar to put pressure on the cover and burst the gasket, then elevate the heads. The aluminum heads should be stored on wood blocks to prevent wear and tear and so the two gaskets can be placed in their appropriate positions on the heads as they are opposite sides of each other and not interchangeable. Cylinder head bolts have to be replaced during the reassembly so as to avoid the development of leaks and overall damage to the engine. Make sure that there are no remains of carbon as well as the existing gasket on the mating surfaces to avoid any future seepage but do not use any sharp metallic elements or abrasives on the block or head surfaces as these could be sources through which some leaks originate from. Check for damages on the surfaces to be torqued then run a thread on the interior of the bolt holes in order to get accurate torque value. Ensure that the new gaskets are fitted correctly over the alignment dowels and if the camshafts are fitted, ensure that they are in their original T.D.C positions for they can be damaged during replacement. Lay the cylinder heads evenly on the block such that the gasket remains unharmed; thereafter fit new bolts and sequence tighten them with a torque wrench attached to a torque-angle adapter. Lastly, the process of installation is the exact opposite of the removal process, but the cooling system must be refilled, the engine oil and filter must be changed and last of all, the engine must be started for leakages to be checked.