My Garage

My Account

Cart

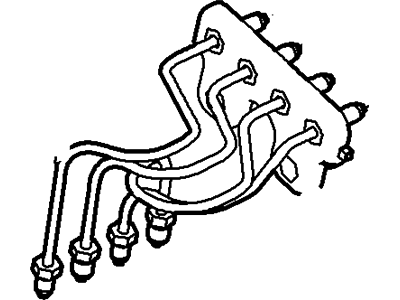

Genuine Ford Explorer Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

70 Brake Lines found

Ford Explorer Brake Hose Assembly

Part Number: 1L2Z-2282-AB$47.86 MSRP: $65.40You Save: $17.54 (27%)Ford Explorer Brake Hose Assembly

Part Number: BB5Z-2282-A$21.66 MSRP: $34.55You Save: $12.89 (38%)Ships in 1-2 Business DaysFord Explorer Brake Hose Assembly

Part Number: FB5Z-2078-A$24.74 MSRP: $39.45You Save: $14.71 (38%)Ships in 1-2 Business DaysFord Explorer Brake Hose Assembly

Part Number: 1L2Z-2078-AB$82.17 MSRP: $112.27You Save: $30.10 (27%)Ford Explorer Brake Hose Assembly

Part Number: DB5Z-2078-F$43.77 MSRP: $71.82You Save: $28.05 (40%)Ships in 1 Business DayFord Explorer Brake Hose Assembly

Part Number: CB5Z-2078-A$43.77 MSRP: $71.82You Save: $28.05 (40%)Ships in 1 Business DayFord Explorer Brake Hose Assembly

Part Number: CB5Z-2078-B$24.74 MSRP: $39.45You Save: $14.71 (38%)Ships in 1-2 Business DaysFord Explorer Brake Hose Assembly

Part Number: DB5Z-2078-E$24.74 MSRP: $39.45You Save: $14.71 (38%)Ships in 1-2 Business DaysFord Explorer Brake Tube Assembly

Part Number: CB5Z-2C296-B$115.68 MSRP: $191.20You Save: $75.52 (40%)Ships in 1-2 Business DaysFord Explorer Brake Tube Assembly

Part Number: DB5Z-2C296-A$115.68 MSRP: $191.20You Save: $75.52 (40%)Ships in 1-2 Business DaysFord Explorer Brake Tube Assembly

Part Number: DB5Z-2C296-B$115.68 MSRP: $191.20You Save: $75.52 (40%)Ships in 1-2 Business DaysFord Explorer Brake Hose Assembly

Part Number: CB5Z-2282-A$21.66 MSRP: $34.55You Save: $12.89 (38%)Ships in 1-2 Business DaysFord Explorer HOSE ASY - BRAKE

Part Number: L1MZ-2282-A$53.78 MSRP: $90.55You Save: $36.77 (41%)Ships in 1-3 Business DaysFord Explorer Brake Tube Assembly

Part Number: XL2Z-2263-AA$27.85 MSRP: $43.27You Save: $15.42 (36%)Ford Explorer Tube

Part Number: F57Z-2234-AA$43.85 MSRP: $68.73You Save: $24.88 (37%)Ships in 1-3 Business DaysFord Explorer HOSE ASY - BRAKE

Part Number: L1MZ-2078-G$68.40 MSRP: $109.09You Save: $40.69 (38%)Ships in 1-3 Business Days

| Page 1 of 4 |Next >

1-20 of 70 Results

Ford Explorer Brake Line

The Ford Explorer Brake Line is one of those parts that help in transferring brake fluid from the master cylinder to the brake caliper pistons to make the hydraulic brake work. Metal brake lines are vulnerable to corrosion as well as impact forces which in one way or the other may cause fluid leaks, loss of the hydraulic pressure. Rubber brake hoses also can be damaged physically and internally, which will, in turn, have negative implications for brakes. If replacement is required, there are pre-bend brake line kit and the corrosion resistant stainless steel hoses that can be fitted easily. One can even and upgrade to a braided stainless steel hoses to get improved a feel of the pedals as well as better responsiveness particularly for performance driving conditions.

We provide a wide range of Ford Explorer Brake Line at the best prices possible. If you need Ford Explorer Brake Line, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford Explorer Brake Line Parts Questions & Experts Answers

- Q: How to inspect and replace brake line and rubber brake hoses on Ford Explorer?A:About every six months, the rubber hoses which connect the steel brake lines with the front and rear brake assemblies should be inspected for cracks, chafing of the outer cover, leaks, blisters and other damage. These are important and vulnerable parts of the brake system and inspection should be complete. A light and mirror will be helpful for a thorough check. If a hose exhibits any of the above conditions, replace it with a new one. Using a flare nut wrench, disconnect the brake line from the hose fitting, being careful not to bend the frame bracket or brake line. Hold the fitting on the hose with a wrench to prevent the metal line from twisting and the frame bracket from bending. Remove the large retaining clip and detach the hose from the bracket and the body. Remove the banjo bolt from the caliper and discard the sealing washers. Connect the hose to the caliper, using new sealing washers. Tighten the banjo bolt. Without twisting the hose, connect the other end of the line to the bracket on the chassis. Connect the metal brake line to the hose fitting by hand, then, using a flare nut wrench, tighten the fitting securely. Be sure to use a wrench on the hose fitting to prevent the bracket from bending or the metal line from twisting. When the brake hose installation is complete, there should be no kinks in the hose. Make sure the hose doesn't contact any part of the suspension. Check this by turning the wheels to the extreme left and right positions. If the hose makes contact, remove it and correct the installation as necessary. When replacing brake lines be sure to use the correct parts. Don't use copper tubing for any brake system components. Purchase steel brake lines from a dealer or auto parts store. Prefabricated brake line, with the tube ends already flared and fittings installed, is available at auto parts stores and dealers. These lines may be available pre-bent to the proper shapes. If pre-bent lines are not available, purchase a straight section the same diameter and length as the original section and use the proper bending tools to shape the new line to match the original. When installing the new line make sure it's securely supported in the brackets and has plenty of clearance between moving or hot components. After installation, check the master cylinder fluid level and add fluid as necessary. Bleed the brake system and test the brakes carefully before driving the vehicle in traffic.

Related Ford Explorer Parts

Browse by Year

2023 Brake Line 2022 Brake Line 2021 Brake Line 2020 Brake Line 2019 Brake Line 2018 Brake Line 2017 Brake Line 2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line 1996 Brake Line 1995 Brake Line 1994 Brake Line 1993 Brake Line 1992 Brake Line 1991 Brake Line