×

- Live Chat

- 1-888-788-9341

My Garage

My Account

Cart

Genuine Lincoln MKX Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Crankshafts found

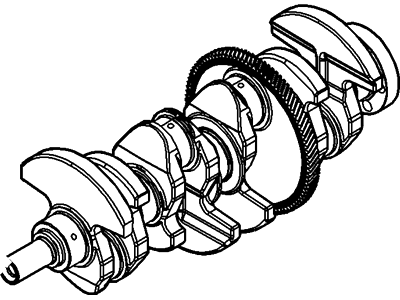

Lincoln MKX Crankshaft Assembly

Part Number: AG9Z-6303-A$693.28 MSRP: $1031.67You Save: $338.39 (33%)Ships in 1-3 Business DaysLincoln MKX Crankshaft Assembly

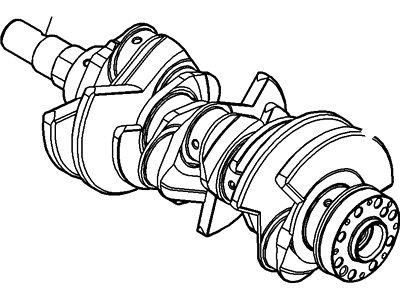

Part Number: HL3Z-6303-A$267.81 MSRP: $395.00You Save: $127.19 (33%)Ships in 1-3 Business Days

Lincoln MKX Crankshaft

We provide a wide range of Lincoln MKX Crankshaft at the best prices possible. If you need Lincoln MKX Crankshaft, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln MKX Crankshaft Parts Questions & Experts Answers

- Q: How is the crankshaft removed on Lincoln MKX?A: The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that various components such as the driveplate, crankshaft pulley, timing chains, oil pan, oil pump body, oil pump drive chain (for 2.7L engines), crankshaft sensor ring, oil filter, engine block skirt stiffener (for 2.7L engines), main cap support brace (for 3.5L and 3.7L engines), and piston/connecting rod assemblies have already been detached. Before removal, measure the crankshaft endplay using a dial indicator or feeler gauges. On 2.0L four-cylinder engines, the thrust bearing is located at the number 3 crankshaft saddle, while on V6 engines, it is at the number 4 crankshaft saddle and bearing cap. If a dial indicator is unavailable, feeler gauges can be used to determine clearance. For 2.7L engines, remove the engine block stiffener bolts and pry the stiffener up, while for 3.5L engines, remove the main bearing cap support brace bolts. Loosen the main bearing cap beam bolts on four-cylinder engines and the main bearing cap bolts on V6 engines until they can be removed by hand. Carefully lift the crankshaft out, ideally with assistance, and reinstall the main bearing caps or lower cylinder block onto the engine block, tightening the bolts finger-tight. For installation, ensure the engine block and crankshaft are clean and inspected. Position the engine block with the bottom facing up, remove any original bearing inserts, and clean the bearing surfaces. Lay new upper main bearing inserts in each main bearing saddle, ensuring oil holes align, and do the same for lower main bearing inserts in the caps. Clean the crankshaft and check the main bearing oil clearance using Plastigage, comparing the width of the crushed material to the scale provided. If the clearance is incorrect, verify that no debris was present during measurement and consider replacing the bearing inserts if necessary. After cleaning all traces of Plastigage, apply a thin layer of grease or engine assembly lube to the bearing surfaces and thrust faces before laying the crankshaft back in place. Clean the bearing insert faces and apply lubricant, ensuring all surfaces are free of oil residue. On V6 engines, apply RTV sealant to the rear main bearing cap parting line and install the cap promptly. Install and torque all bolts in the correct sequence, then recheck the crankshaft endplay. Rotate the crankshaft to check for binding, ensuring it rotates smoothly. For 2.7L engines, install a new oil seal and the engine block stiffener, aligning it properly and tightening the bolts within the specified time frame. For 3.5L and 3.7L engines, install the main cap support brace and tighten the bolts accordingly.