My Garage

My Account

Cart

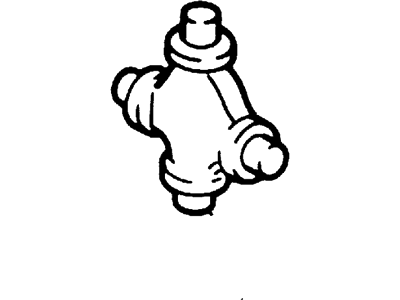

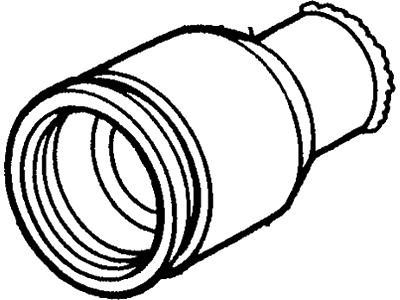

Genuine Ford F-250 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Universal Joints found

Ford F-250 U-Joint Repair Kit

Part Number: F2TZ-4635-B$73.36 MSRP: $107.25You Save: $33.89 (32%)Ships in 1-3 Business DaysFord F-250 U-Joint Repair Kit

Part Number: F2TZ-4635-C$27.45 MSRP: $37.51You Save: $10.06 (27%)Ships in 1-2 Business DaysFord F-250 KIT - UNIVERSAL JOIN

Part Number: E3TZ4635B$18.29 MSRP: $24.99You Save: $6.70 (27%)Ships in 1-2 Business DaysFord F-250 U-Joint Repair Kit

Part Number: C3AZ-4635-M$18.37 MSRP: $25.11You Save: $6.74 (27%)Ships in 1-2 Business DaysFord F-250 U-Joint Repair Kit

Part Number: C3AZ-4635-L$10.62 MSRP: $14.75You Save: $4.13 (28%)Ships in 1-2 Business DaysFord F-250 U-Joint Repair Kit

Part Number: F3TZ-4635-A$24.17 MSRP: $35.33You Save: $11.16 (32%)Ships in 1-2 Business DaysFord F-250 U-Joint Repair Kit

Part Number: F2AZ-4635-A$42.13 MSRP: $61.60You Save: $19.47 (32%)Ships in 1-3 Business DaysFord F-250 U-Joint Repair Kit

Part Number: F2TZ-4635-E$25.08 MSRP: $36.67You Save: $11.59 (32%)Ships in 1 Business Day

Ford F-250 Universal Joint

Universal Joint in Ford F-250 plays a very important part in the attachment of the vehicle's driveshaft to the differential since it enables the requisite movement when there is shifting in the vehicle's suspension system based on the terrains. This joint allows for flexibility of the driveshaft to allow variations of angle in components. Normally, another Universal Joint will also be found at the front and rear of the of the driveshaft, where the front end hooks on the transmission slip yoke while the rear end hooks on the differential yoke or flange. Made in a way that has the cross and needle bearings placed in the hardened steel cups the Universal Joint is made to last. Universal JointS purchased from the factory are ready to use, and the option comes with a grease zerk for application. It is worth to note that over time, there exist certain alterations in Universal Joint but fundamentally speaking, the operating principle has not changed. Worn Universal Joints cause visible negative effects including, loud sounds like thumping and shaking which can only be addressed by regular inspection and replacement so that the Ford F-250 works properly.

We provide a wide range of Ford F-250 Universal Joint at the best prices possible. If you need Ford F-250 Universal Joint, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Ford F-250 Universal Joint Parts Questions & Experts Answers

- Q: How to repair different types of universal joints, including outer snap-ring, injected plastic, and double cardan type constant velocity joints on Ford F-250?A:To service the outer snap-ring type universal joint, first, remove the driveshaft and mark the joint yokes' positions. Extract the snap-rings from the bearing cups, then use sockets or pipe pieces in a vise to press one cup while displacing the opposite one into a larger socket, gripping and twisting the bearing cup out with pliers. Clean the yoke and inspect for damage, then obtain a repair kit that includes trunnion, cups, needle rollers, seals, washers, and snap-rings. Before reassembly, pack grease into the trunnion reservoirs and needle bearings without displacing them. Position the trunnion in the yoke, partially install one cup, insert the trunnion, partially install the opposite cup, center the trunnion, and press both cups into place using sockets slightly smaller than the bearing cups, ensuring needle bearings remain in place. Install the snap-rings and align the shaft yokes to install the other bearing cups similarly. For the injected plastic type, destroy the production line plastic retainers and fit conventional snap-ring repair kits. Support the joint yoke in a press and use a forked tool to apply pressure to eject the bearing cups, then twist them out with a vise. Clean any plastic remnants and obtain a repair kit with a prelubricated trunnion assembly and other components. Assemble the joint, noting that snap-rings are installed inside the yokes, and if the joint is stiff after reassembly, apply hammer blows to free the bearing cups. For the double cardan type constant velocity joint, use an inspection kit to dismantle the joint for inspection, marking the flange and coupling yokes for reassembly. Disengage the flange yoke and trunnion from the centering ball, remove the seal, washers, spring, and ball seats, then clean and inspect all components for wear, replacing any damaged parts. Remove plastic from the coupling yoke groove if necessary, inspect and replace the centering ball if damaged, and press a new ball onto the stud. Lubricate all parts with grease from the repair kit and insert them into the ball seat cavity in the correct order, lubricate the seal lips, and press it into the cavity, filling it with grease. Finally, install the flange yoke to the centering ball, ensuring alignment marks are correct, and install the trunnion caps as previously described.

Related Ford F-250 Parts

Browse by Year

1999 Universal Joint 1998 Universal Joint 1997 Universal Joint 1996 Universal Joint 1995 Universal Joint 1994 Universal Joint 1993 Universal Joint 1992 Universal Joint 1989 Universal Joint 1988 Universal Joint 1987 Universal Joint 1986 Universal Joint 1985 Universal Joint 1984 Universal Joint 1983 Universal Joint 1982 Universal Joint 1981 Universal Joint 1980 Universal Joint