×

- Live Chat

- 1-888-788-9341

My Garage

My Account

Cart

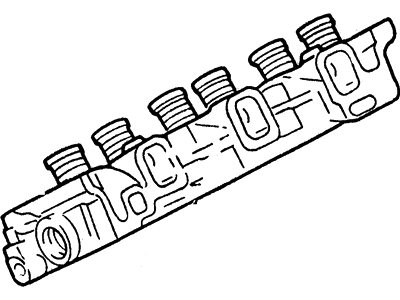

Genuine Lincoln Mark VII Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

Lincoln Mark VII Cylinder Head

We provide a wide range of Lincoln Mark VII Cylinder Head at the best prices possible. If you need Lincoln Mark VII Cylinder Head, you can shop with confidence on our website. All our OEM parts come with a manufacturer's warranty and are delivered to your door step with a fast delivery service.

Lincoln Mark VII Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install cylinder heads on Lincoln Mark VII Overhead valve (OHV)engines?A: Remove the valve cover(s), Pushrods, intake manifold, drive belts, idler pulley bracket, Thermactor valve and pump, and crossover tube first. For the left cylinder head, take out and unbolt the air conditioning compressor and bracket(s). Disconnect the fuel line from the right cylinder head and remove the exhaust manifold(s). Then draw on cardboard around each cylinder and bolt pattern using a new head gasket. Loosen the head bolts in 1/4 turn increments; store them; then lift off the heads. When installing, clean surfaces; check for damage; chase holes for bolts; position new gasket(s). Put heads in place on the block after oiling bolt threads and tighten them according to this sequence. Finally, perform the reverse order of the remaining steps plus change the engine oil & filter before starting the engine.

- Q: How to reassemble a clean head after valve service on Lincoln Mark VII?A: Regardless of whether or not the head was sent to an automotive repair shop for valve servicing, make sure it's clean before beginning reassembly. If the head was sent out for valve servicing, the valves and related components will already be in place. On all engines, lubricate and install the valves, then install new seals on each of the valve guides. Using a hammer and deep socket, gently tap each seal into place until it's seated on the guide. On OHC engines, reinstall the valve lifters. Beginning at one end of the head, lubricate and install the first valve. Apply moly-base grease or clean engine oil to the valve stem. Drop the spring seat or shim(s) over the valve guide and set the valve spring, retainer (or rotator) and sleeve (if used) in place. Apply a small dab of grease to each keeper to hold it in place. Compress the springs with a valve spring compressor and carefully install the keepers in the upper groove, then slowly release the compressor and make sure the keepers seat properly. Repeat the procedure for the remaining valves. Be sure to return the components to their original locations - don't mix them up! Check the installed valve spring height with a ruler graduated in 1/32-lnch increments or a dial caliper. If the head was sent out for service work, the installed height should be correct. The measurement is taken from the top of each spring seat or shim(s) to the bottom of the retainer. If the height is greater than the figure, shims can be added under the springs to correct it. Caution: Don't, under any circumstances, shim the springs to the point where the installed height is less than specified. Apply moly-base grease to the rocker arm faces and the fulcrums, then install the rocker arms and fulcrums on the cylinder head studs.

- Q: How to disassemble and inspect cylinder heads on Lincoln Mark VII?A: Dealerships and auto parts shops sell new and rebuilt cylinder heads. One would require some specialized tools for dissembling and inspecting it. Buying replacement heads may be more feasible than trying to find replacement parts. When disassembling the cylinder head, remove valves and rocker arm components then label or store them separately. Use a spring compressor in removing the keepers and other parts.

- Q: How to remove and install cylinder heads on Lincoln Mark VII Overhead cam (OHC) engine?A: The engine must be completely cool when the heads are removed. Failure to allow the engine to cool off could result in head warpage. Removal begins with disconnecting the cable from the negative battery terminal and removing the valve cover(s). Next, remove the intake manifold, timing chain cover, and timing chains. Use the required camshaft holding fixture to lock the camshafts in place. Leave the holding fixtures in place until after the reassembly is complete. Separate the exhaust manifold-to- exhaust pipe(s). Detach the positive battery cable bracket at the rear of the cylinder head. Loosen the nut and slide the positive battery cable bracket up and off the stud on the right side of the cylinder head. At the rear of the right cylinder head remove the ground strap. Disconnect the heater hose at the pipe fastened at the rear of the right side cylinder head. The pipe can remain attached to the head during removal. Remove the exhaust manifold(s), if desired. Remove the head bolts by loosening them 1/4 turn at a time. Lift the head(s) off the engine. Remove the old head gasket(s). Before removing, note which gasket goes on which side, they are different and cannot be interchanged. Cylinder head disassembly and inspection procedures are covered in detail. Installation begins with ensuring the mating surfaces of the cylinder heads and block are perfectly clean. Use a gasket scraper to remove all traces of carbon and old gasket material, then clean the mating surfaces with lacquer thinner or acetone. Check the block and head mating surfaces for nicks, deep scratches and other damage. Use a tap of the correct size to chase the threads in the head bolt holes. Make sure the new gaskets are on the correct cylinder banks. Position the new gasket(s) over the alignment dowels in the block. Before placing the cylinder heads back on the block, rotate the crankshaft counterclockwise, as you are facing the engine, so the keyway is in the 9 o'clock position. Carefully position the head(s) on the block without disturbing the gasket(s). Install the NEW head bolts and follow the recommended sequence and tighten the bolts, in three steps. The remaining installation steps are the reverse of removal. Change the engine oil and filter, then start the engine and check carefully for oil and coolant leaks.

- Q: How to prepare the cylinder head(s) and associated valve train components for an engine overhaul on Lincoln Mark VII?A: To embark on an engine overhaul, the first step is to prepare the cylinder heads and valve train parts by cleaning and inspecting them. Take off any old gasket material and sealing compound from the surfaces. Use a solvent, dry it, and clean all parts thoroughly. The crack inspection process of the cylinder head starts with a visual check for cracks or other signs of damage. Check for warpage with a straight edge. Examine the valve seats as well as measure valve stem-to-guide clearance. Inspect valves for wear and imperfections. Check valve margin width. Look at the valve springs for wear and take free lengths measurements. Confirm retainers' condition along with their keepers'. Inspect rocker arm components for wear. Assess pushrods as well as rocker arm studs for damage. Replace any parts that have either worn out or are damaged in any way in this section.